Centerless Grinding

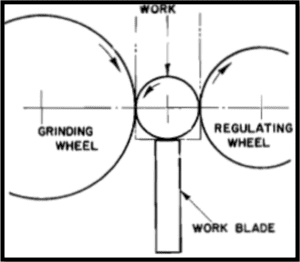

In centerless grinding, the workpiece is located between two abrasive wheels rotating the same direction at different speeds. The workpiece rests on a platform between the two wheels. By varying the pressure applied to the workpiece by the abrasive wheels, material is removed from the workpiece. Precise pressure adjustments allow precise amounts of material removal.

Types of Centerless Grinding

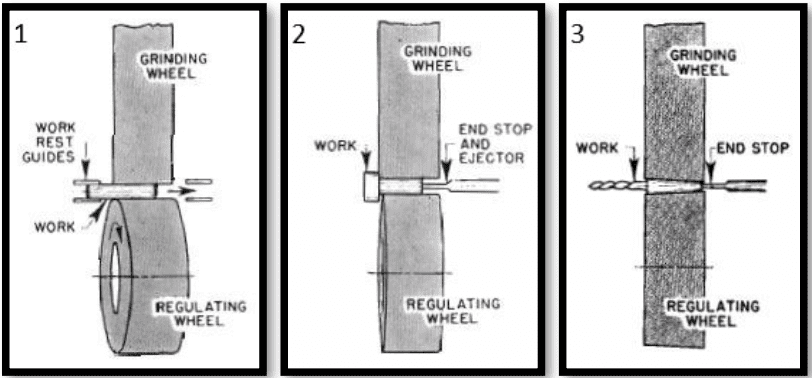

1.) Thru-feed. The workpiece is passed through the abrasive wheels allowing precise material removal from straight, cylindrical surfaces without shoulders or flanges.

2.) In-feed. Usually for cylindrical workpieces with a shoulder or multiple diameters. The workpiece rests against a stop that only allows material removal from the specified diameter.

3.) End-feed. Used mainly for taper grinding. One or both abrasive wheels are dressed to the desired taper and the workpiece is fed from one end to a fixed stop, thus removing material and achieving the desired taper on the workpiece.

ETI INC. CENTERLESS Grinding capability

Types: Thru-feed and In-feed

Materials: Ferrous and Non-Ferrous Metals

Workpiece OD: 0” to 3”

Lengths: Up to 15’

Diameter Tolerance: 0.0003” and greater

Surface finish: 32 RMS and greater

Quantities: Single piece to Full Production

APPLICATIONS

Aerospace, Oil Field, Bar Processing, Industrial, Prototype